What’s AI for manufacturing anyways?

To run a manufacturing shop floor with any level of success, most definitely you are already aware of the importance of digital management. Probably pretty good at it in essence.

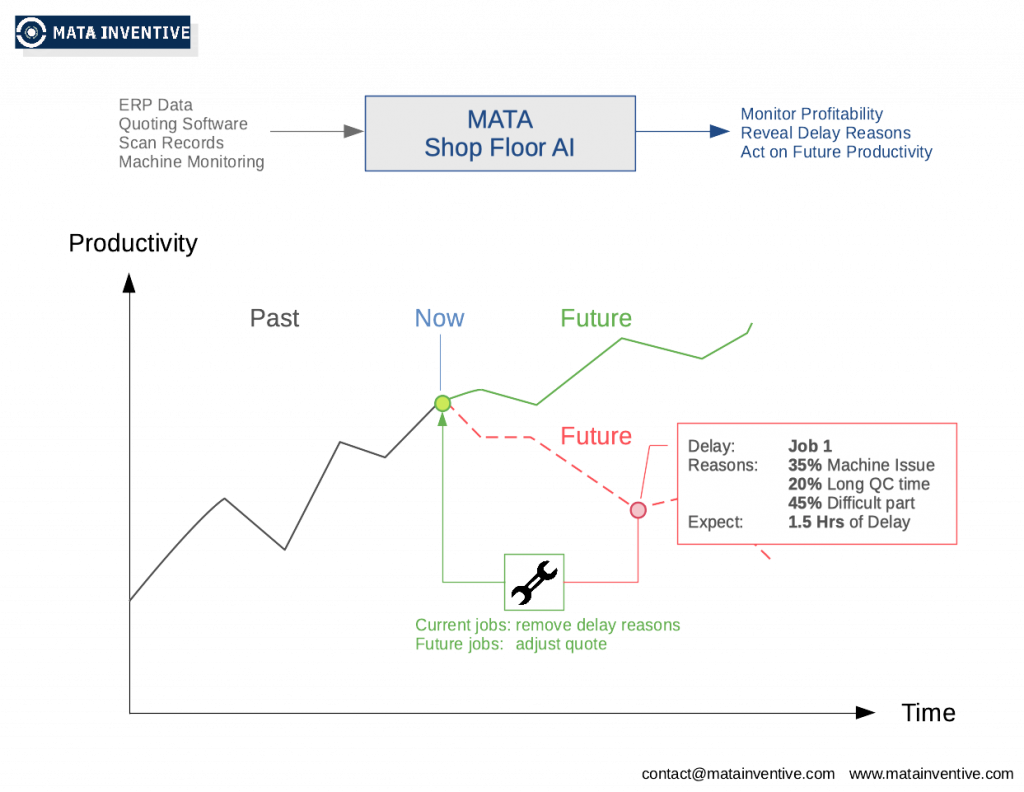

AI is a way to utilize your existing data to predict what’s going to happen in the future. Though we all know shop floor is full of changes, the dynamics usually don’t as often. For example: you may not be able to be certain how long your next job would take, but you can know quite certainly that certain tools tend to break more often than others, and certain equipments are more prone to breakdowns than the rest. What AI can do is to factor all those signals in, and create a highly accurate model to help you face the unknown with the best clue in hand.

What’s the risk?

There is always a risk involves when making a business decision. When adopting new manufacturing technology, we usually recommend to start with the most tangible goals first.

Some may say the lowest hanging fruit is live utilization monitoring. We disagree. The truth is, that does have the most immediate effect for large facilities. However, a per-machine installation is not a small fee and therefore is definitely the lowest hanging fruit in terms of performance, not in terms of cost. For small to medium facilities, though the investment for a per-machine IoT installation is much less, the benefit is much less as well as your highest concern might not be running the machines 24-7, but to bring jobs of higher profitability in.

The best way, in our opinion, is from utilizing your existing data. If you already have enforced job scanning and schedule the jobs accordingly (Doesn’t need to be a perfect schedule, it’s our goal not where we start with), then a powerful AI can serve you a lot more benefit than you can imagine. You can check out an introduction to how AI assists shop floor management here.

What kind of performance should I expect?

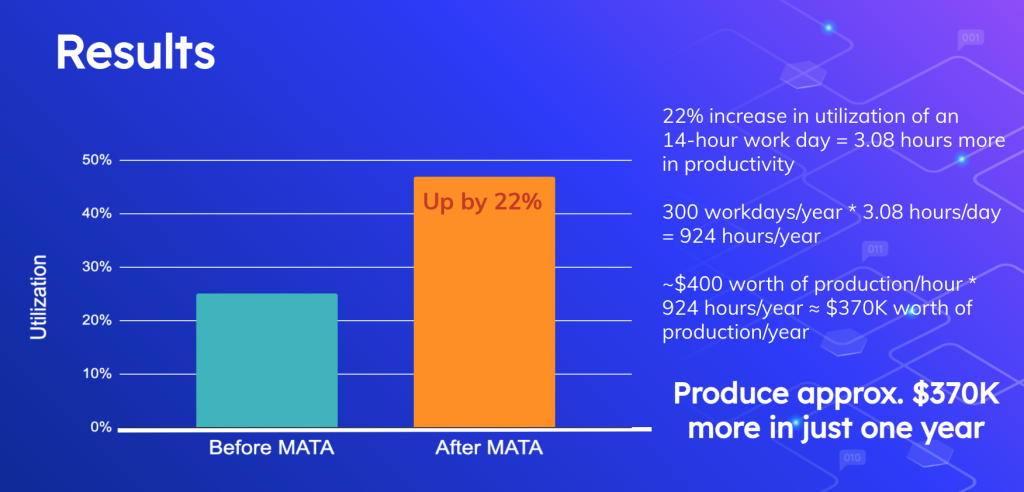

Given MATA’s cost effective monitoring and accurate AI prediction, manufacturers can address their potential bottlenecks before they happen. More importantly, to adjust their quotes accurately to ensure on-time delivery while maintaining competitive pricing. Our clients typically see 20%+ increase in productivity and are able to save hours of data crunching time each week by using the AI to summarize the shop efficiency and prioritizing important job items to supervise.

That being said, it must be noted that success only comes from close collaboration between the AI product provider and the shop floor management. A cookie-cutter product is never a good idea when it comes to solving your shop floor problems.

Does it work for our process?

Good news is a good AI product can adapt to your manufacturing needs without any problem. Bad news is, there needs to be a culture on the shop floor that can adopt to new technology and embrace the benefit of it. Contact us if you would like to evaluate what works the best for your shop floor.

Mata Knowledge