Real-time temperature monitoring of machinery and equipment: By placing temperature sensors on critical machinery and equipment, you can monitor their temperature in real-time and detect anomalies, such as overheating or temperature fluctuations, that may indicate potential problems.

Early warning system for machine failure: Temperature monitoring can serve as an early warning system for potential machine failure. By monitoring the temperature of equipment, you can detect when it is running at a higher temperature than normal, indicating a potential issue that needs to be addressed.

Preventive maintenance: By monitoring temperature data over time, you can identify trends and patterns that can help you predict when equipment maintenance is necessary. This can prevent unexpected downtime and increase the lifespan of machinery.

Quality control: Temperature monitoring can be used to ensure that production processes are operating within the specified temperature range, ensuring consistent quality of products.

Environmental monitoring: Temperature sensors can be used to monitor the temperature of the surrounding environment, ensuring that sensitive materials are stored in the appropriate temperature range.

Food safety: Temperature monitoring is critical in the food industry to ensure that perishable items are stored and transported at the correct temperature to prevent spoilage and contamination.

Energy efficiency: Temperature monitoring can help identify areas where energy efficiency improvements can be made. By monitoring the temperature of machinery and equipment, you can identify areas where energy is being wasted, and take steps to optimize performance and reduce energy consumption.

Predictive maintenance: By using machine learning algorithms to analyze temperature data, you can predict when equipment failures are likely to occur, allowing you to schedule maintenance before a failure occurs.

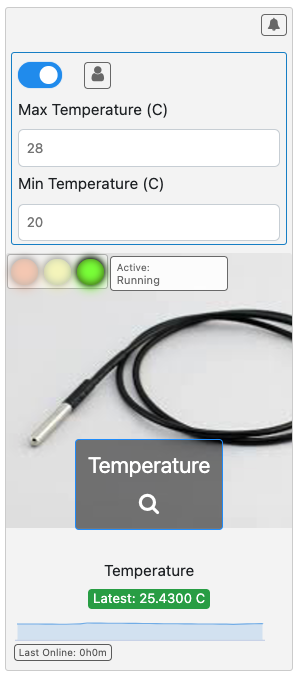

Remote monitoring: Temperature monitoring can be conducted remotely, allowing you to monitor equipment and machinery in remote locations or areas that are difficult to access.

Compliance: Temperature monitoring is often required by regulatory bodies to ensure compliance with safety and environmental standards. Industrial IoT temperature monitoring solutions can help ensure compliance by providing real-time data and alerts when temperature ranges are exceeded.