Introducing ArbIt: The first industry 4.0 out-of-the-box SaaS Solution.

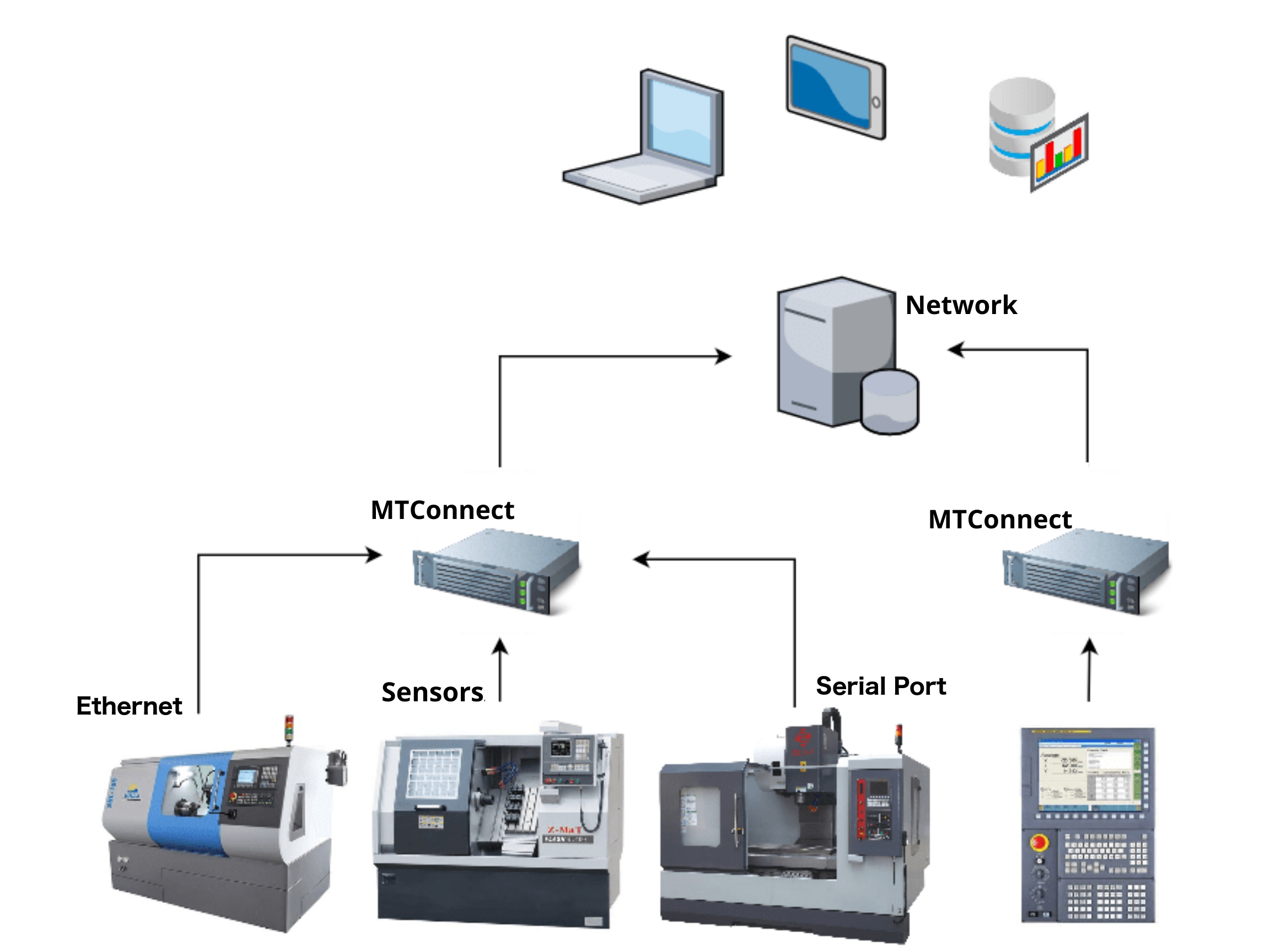

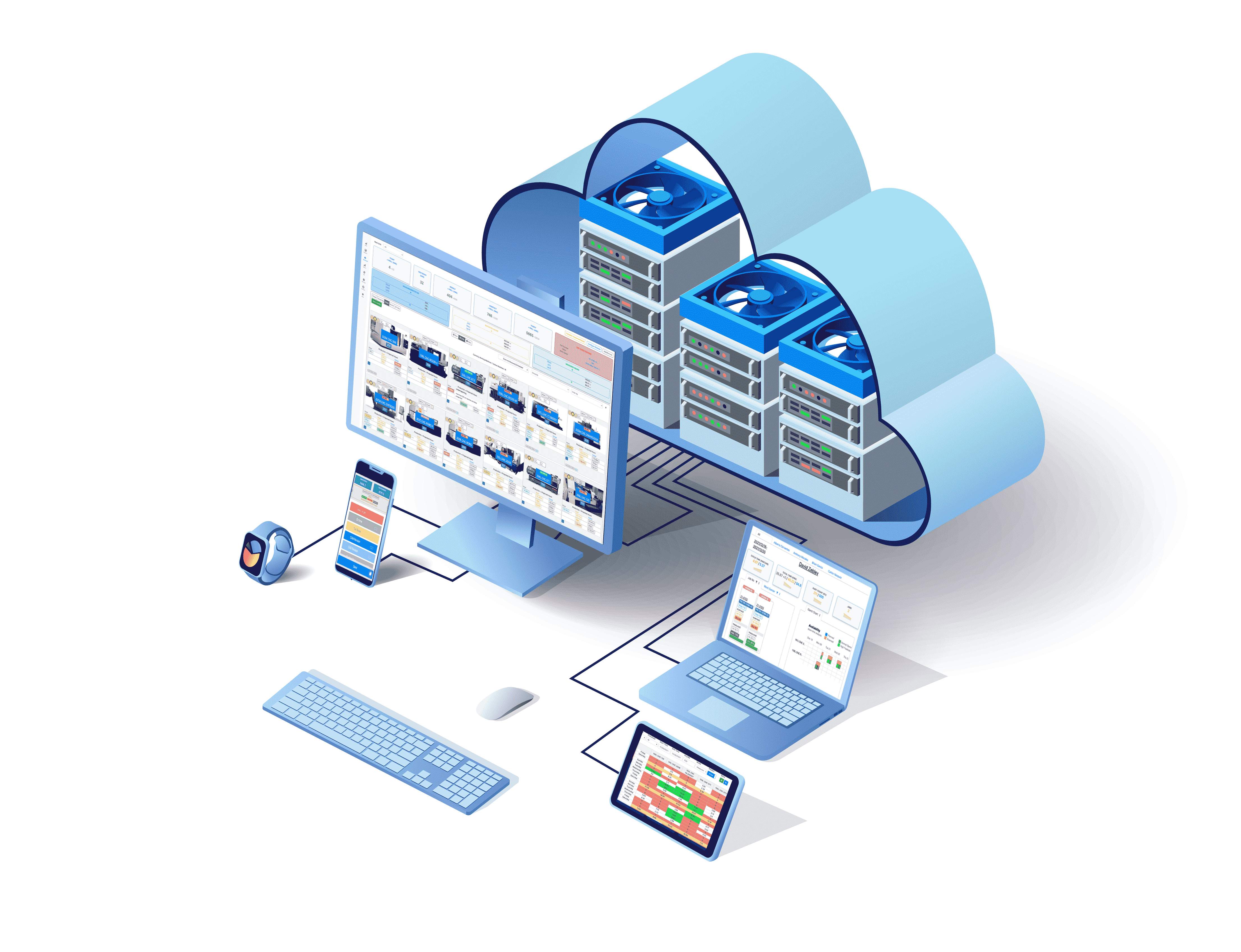

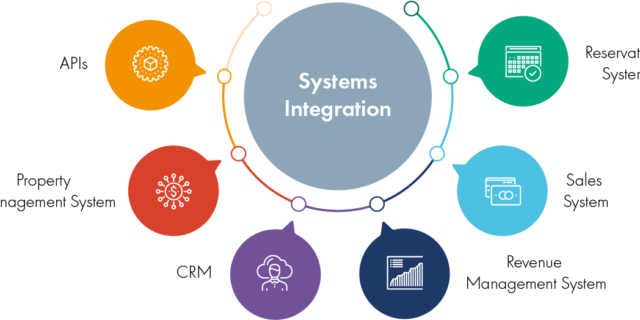

Connect Key Data Sources

From trapped data to smart

data, our APIs connect

any quoting, ERP, MES

& equipment.

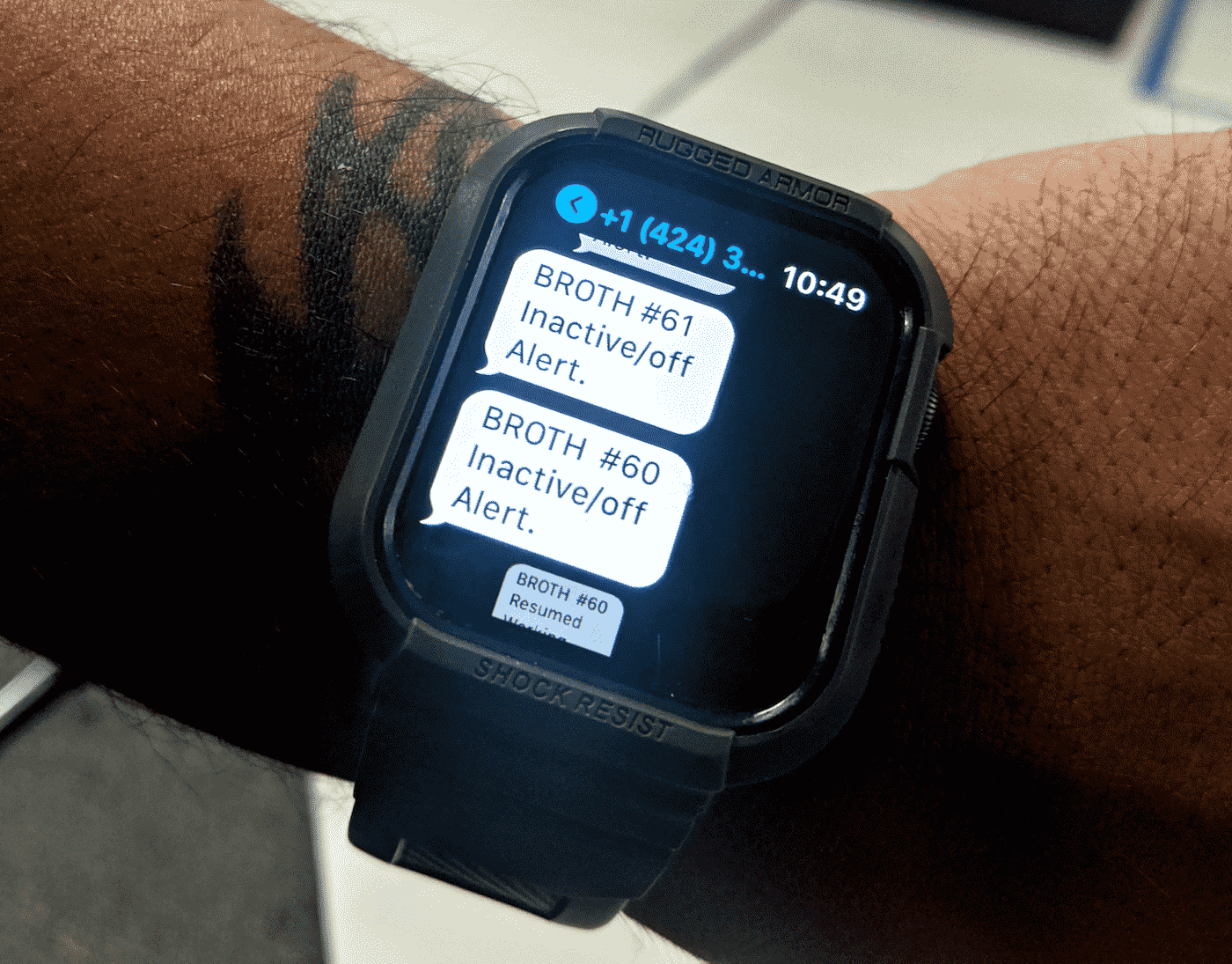

Provide Actionable Insights

Across Your entire organization: Managment, Engineering, Operations, & Sales.

Maximize Asset Utilization

Eliminate bottlenecks of personnel, equipment, parts, & process to speed up your entire operation 40%+.

A Journey of Digital Transformation

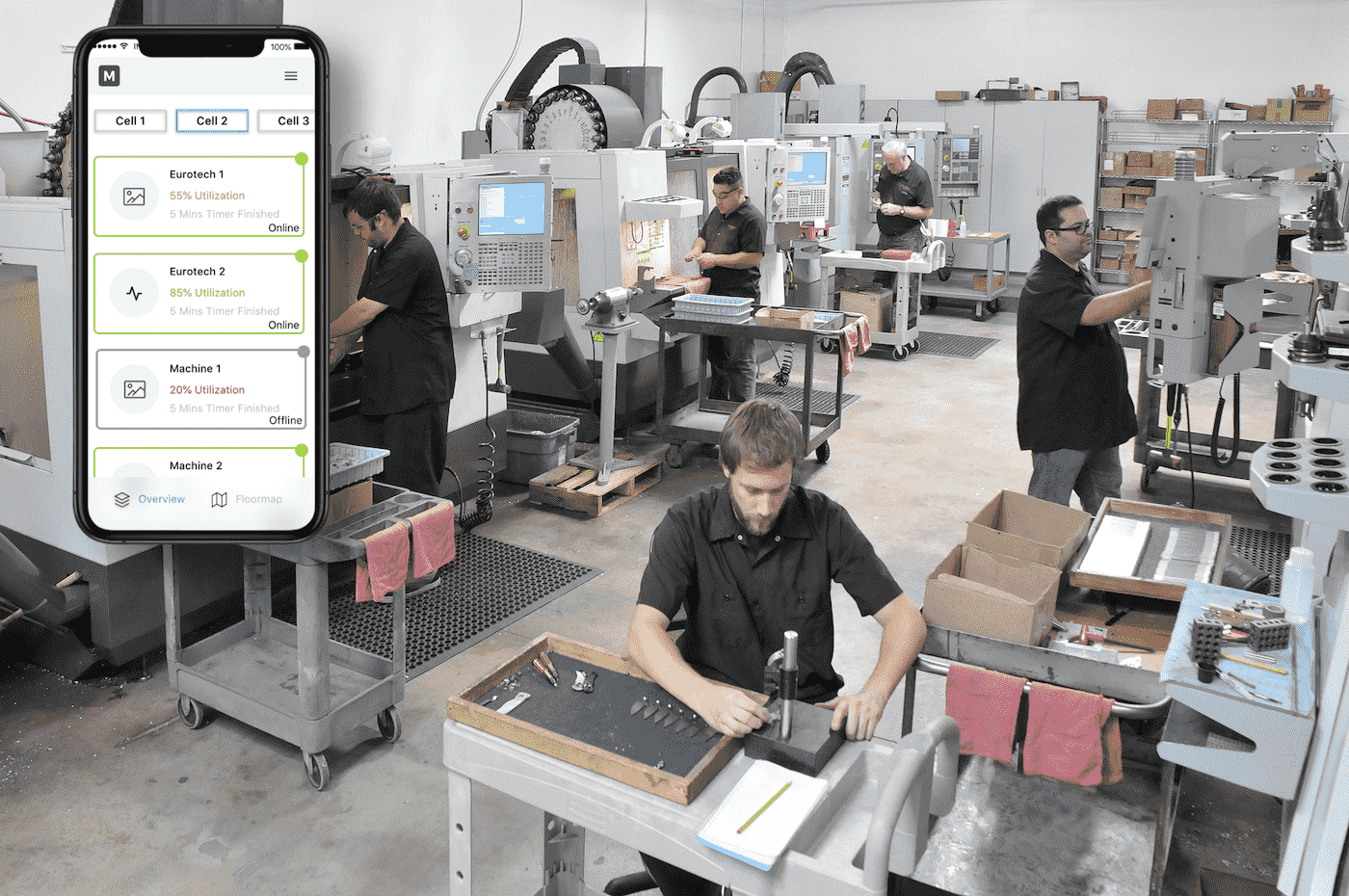

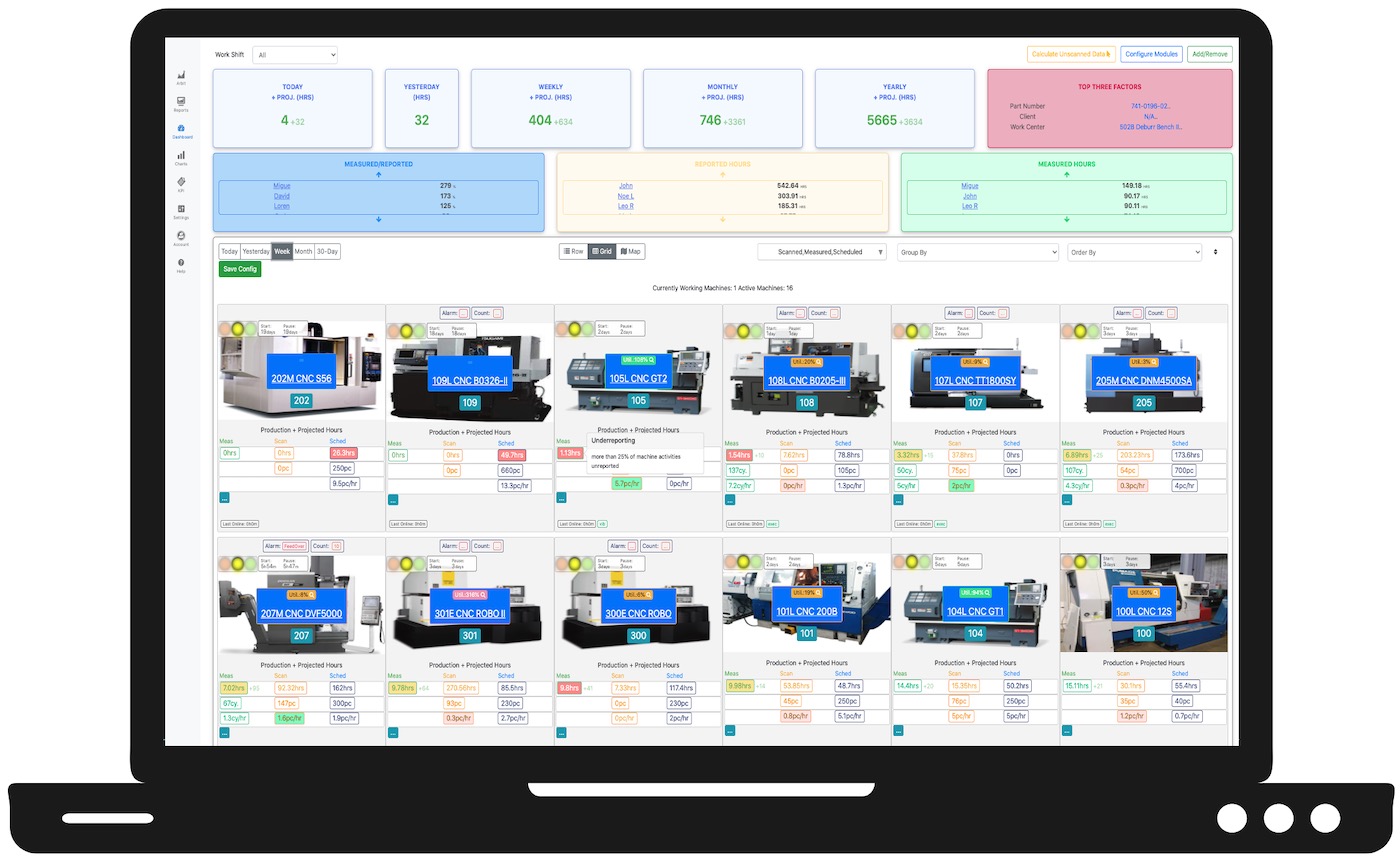

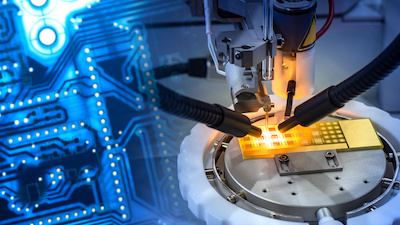

Industry 4.0 Machine Monitoring

Simplicity with Software

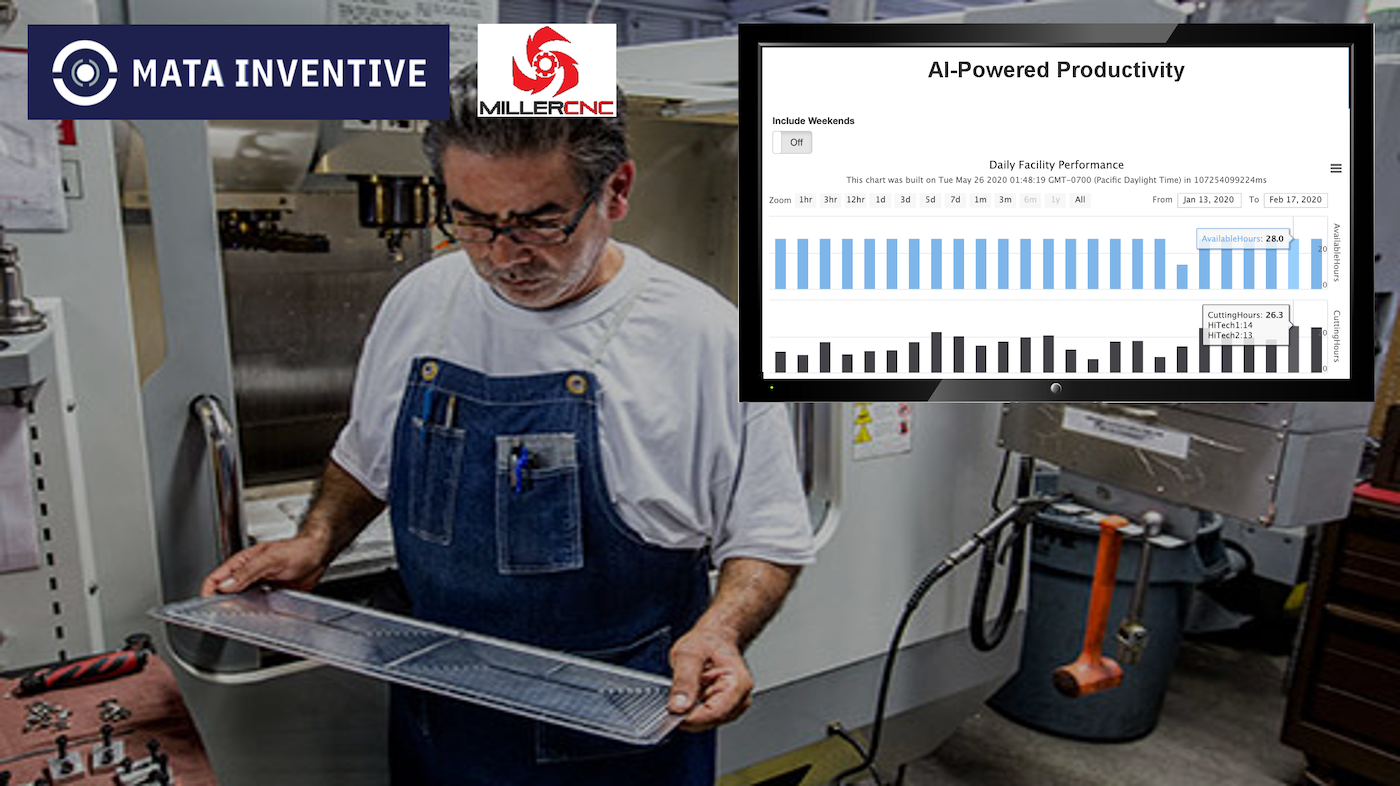

ArbIt in Action

Mata Inventive’s artificial intelligence is optimized for your operation’s specific needs.

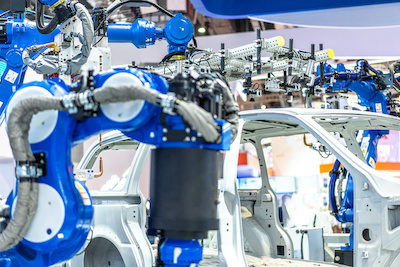

Who We Help

Through an agile approach to equipment monitoring and data connectivity, no operation is too unique to take advantage of Mata Inventive's out-of-the-box AI solution.

- All

- Industries

- Equipment

Aerospace Industry

Commercial Aerospace, Rockets, Satellite, VTOL, Military and Defense

Automobile Industry

Electric Vehicles, Autonomous Vehicles, Structural and Cosmetic, Lighting, Interior and Exterior

Clothing and Apparels Industry

Textile Mills, Textile Product Mills, and Apparel Manufacturing

Electrical Equipment, Appliances & Components

Power Station, Electric Power Transmission, Electricity Distribution, Consumer Electronics, Industrial Electronics

Food and Beverages

Bottling, Canning, Temperature-controlled & Pressure-cooked food items

Petroleum, Coal, Chemicals, Plastics and Rubber

Mining, Energy and Renewables

Horizontal CNC Machines

Sensors in CNC machines are used to keep a track of CNC machine's performance, production efficiency, and resource analysis.

Drilling Machines

Sensors are used to measure surface data like weight on bit, annulus and internal pressure, and annulus and instrument temperature while drilling.

Grinding Machines

Sensors are used to measure data to help in grinding wheel positioning and grinding wheel temperatures for a perfect job.

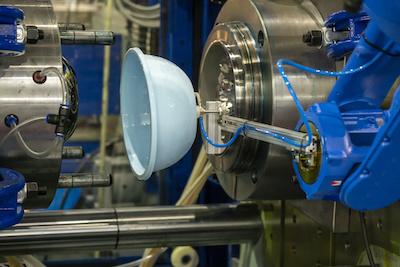

Injection Molding Machines

Sensors are used to measure in-mold temperature and pressure to avoid quality issues and increase mold efficiency.

Turning Machines

Sensors in CNC machines are used to keep a track of CNC machine's performance, production efficiency, and resource analysis.

Milling Machines

Sensors on milling machines are used to measure signals such as cutting pressure, vibration and temperature around the milling tool.

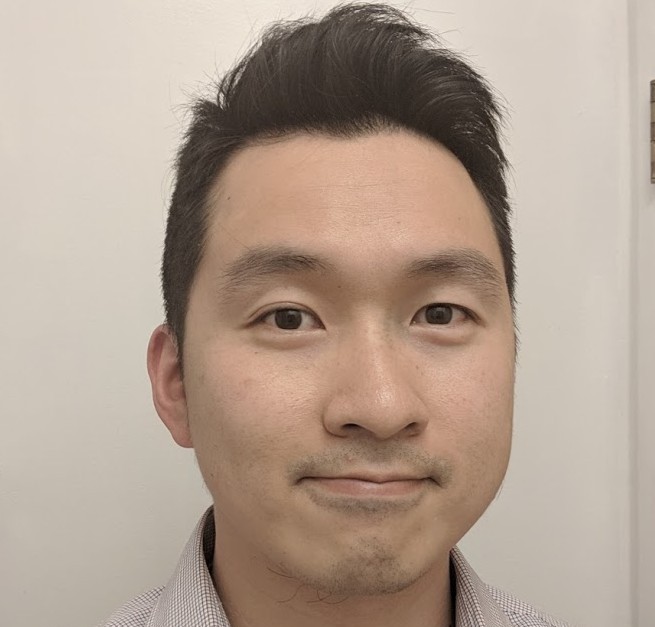

Our Leadership

Educated, Experienced, Hardworking and Creative, our team will engineer a solution that solves your toughest challenges

YenChi Chang

Founder and Chief Executive Officer

Zakary Smith

PartnerAbout Us & Values

Mata Inventive is a California, USA, based engineering firm specializing in software, embedded firmware and electro-mechanical hardware with 50+ years of experience. This results in an analytics powerhouse that uses shop floor data to visualize your production efficiency with AI-generated actionable insights.

Values Foundation

Clients

These customers trusted us to make their shop floor "smart" using MATA's expertise and unique approach towards achieving greater profitability!

Technical Articles

Our Products

Connector Software Add To Cart

Integration

Included in Plans

Included in Plans

Our Plans

Subscription as a Service

-

Machine Monitoring Hardware - Machine Monitoring Firmware

-

Hardware Installation – Self Setup - Hardware Installation – White Glove

- Software Connector

- Cloud Server

- On-Premises Server

- Factory Management Console

- Updates

- Bug Fixes

Perpetual License

-

Machine Monitoring Hardware - Machine Monitoring Firmware

-

Hardware Installation – Self Setup - Hardware Installation – White Glove

- Software Connector

- Cloud Server

- On-Premises Server

- Factory Management Console

- 12 months Updates

- 12 months Bug Fixes

Machine Monitoring Only

-

Machine Monitoring Hardware - Machine Monitoring Firmware

-

Hardware Installation – Self Setup - Hardware Installation – White Glove

- Software Connector

- Cloud Server

- On-Premises Server

- Factory Management Console

- 12 months Updates

- 12 months Bug Fixes

Software Connector Only

-

Machine Monitoring Hardware - Machine Monitoring Firmware

-

Hardware Installation – Self Setup - Hardware Installation – White Glove

- Software Connector

- Cloud Server

- On-Premises Server

- Factory Management Console

- 12 months Updates

- 12 months Bug Fixes

Frequently Asked Questions

-

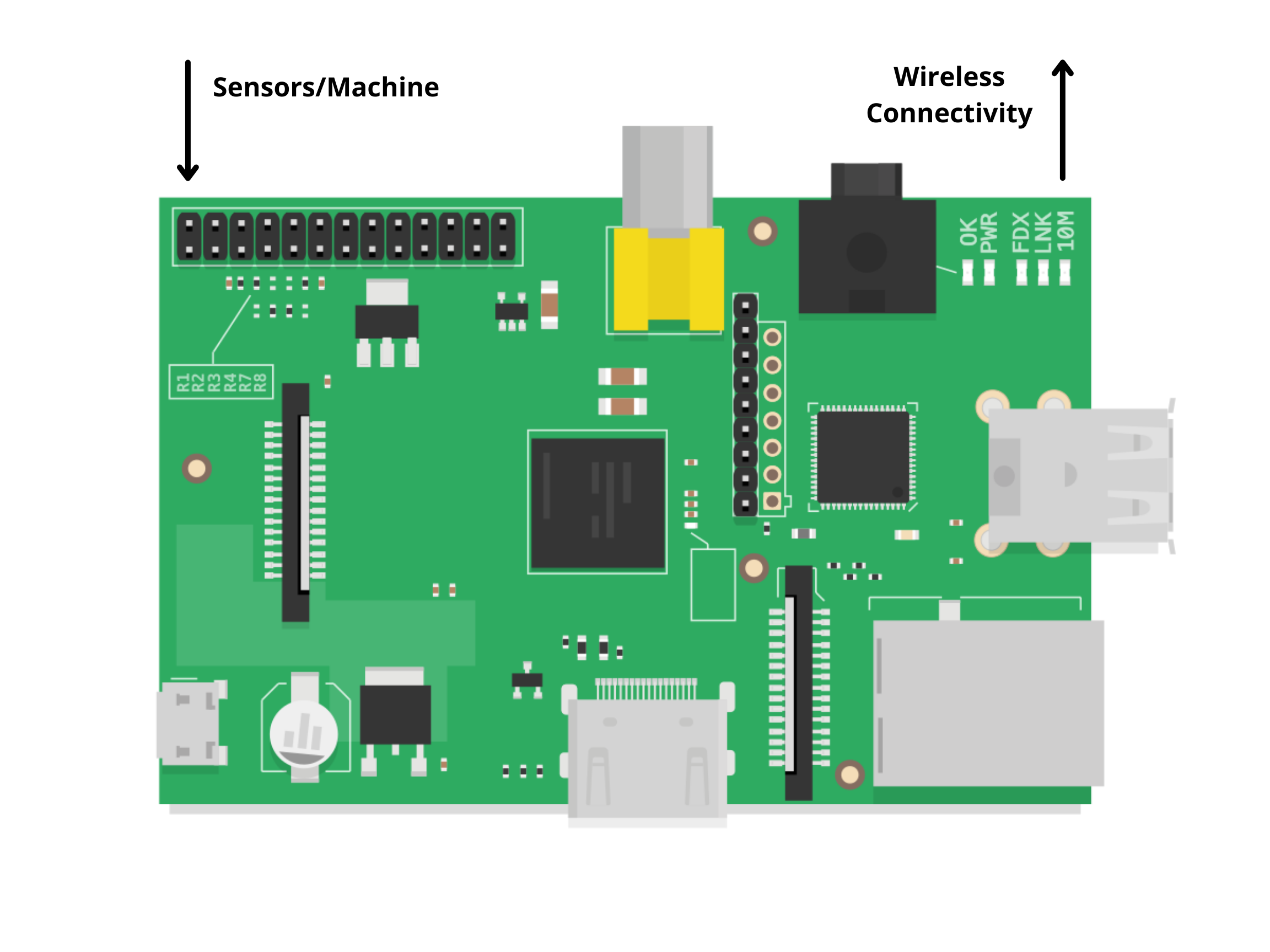

How does the System Work?

We install a palm-size monitoring device that is pre-provisioned and automatically calibrates within 24 hours of self installation. The device collects and summarizes data into actionable insights through easily digestible dashboards.

-

Does it interfere with our current system?

Since MATA does not require any manual input, it boosts shop floor transparency without any interference with the current workflow. It actually leverages your current workflow by taking readily available data and leverages this through Arbit, our AI engine, to find hidden trends for improvement.

-

Do I need to train the technicians to use it?

Since the system is automatic, the technitians do not need any training. The shop efficiency data can also be conveniently available from the executives to the technitians fingertips as well as on the manager’s screen.

-

What does the system tell me?

The system reveals the true machine utilization number without any manual input. Our data shows which machine/job has long cycle time, long set up time, machine idle time, and key performance indicators for staff, machines, clients, part numbers and much more.

-

Are my machines too old for it?

Our monitoring device is compatible with any equipment you have, even for machines that don't have any ethernet/serial port available.

Location:

18136 Oxnard Street Unit #41

Tarzana, CA 91356-1733, USA

Email:

info@matainventive.com

Call:

+1 415 622 5692