Arbit

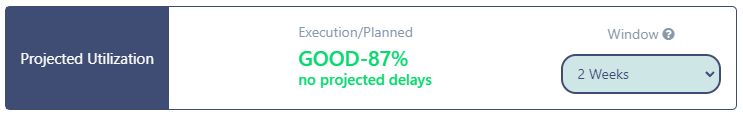

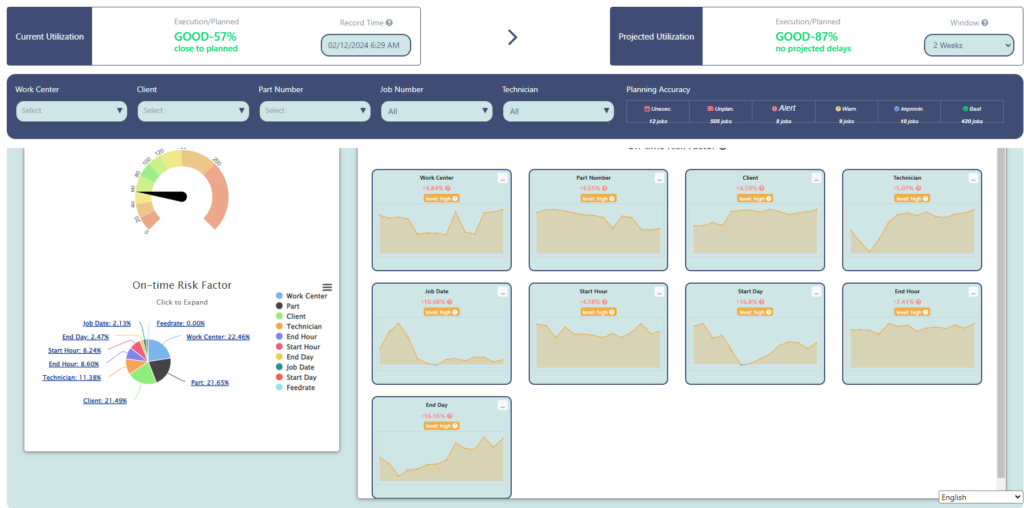

Arbit or commonly known as forecasting is the VIP in MataInventive’s AI! This includes predicting projected utilization based on the current utilization data. The current utilization data is the real-time data incoming from the machines/ERP systems from the shop and after running high-level data analytics on it, we create and forecast the projected utilization. This is based on a lot of factors like ‘Work Center’, ‘Client’, ‘Part Number’, ‘Job Number’, ‘Technician’. We predict factors like:

- Unexpected Jobs: Jobs not executed as scheduled

- Unplanned Jobs: Jobs executed as per schedule

- Alerts on Jobs: Executed > Planned hours with delay alerts

- Warnings on Jobs: Executed > Planned hours without delay alerts

- Good Jobs: Executed < Planned hours with delay alerts

- Best Jobs: Executed > Planned hours without delay alerts

In this section, we can change the ‘Record Time’ which is the date of measurement of which data will be considered to be modeled and used for future predictions based on the measurement window set in projected utilization. The projected utilization is a result of optimum use of predictive modeling to find future trends and performance metrics for the machines (work centers) on the shop floor. You can change the metrics as per your requirement and see the magic! Our AI model will accurately predict give out accurate results based on historical data.

The Planning Adjustment Factor is the adjustment factor for the record time /quoted time in order to safely deliver the job on time. This number or factor should be as close to 0% as possible. If the number is below 0%, it means that the planning of jobs can be more aggressive. If the number of factor is above 0%, it means that some adjustment and extensive planning is needed to deliver the assigned job on time. The On-time risk factor is one more metric which determines the ability of the machine/work center to deliver the job on-time. Higher the value of this factor, more it is influences on-time deliver of the job.

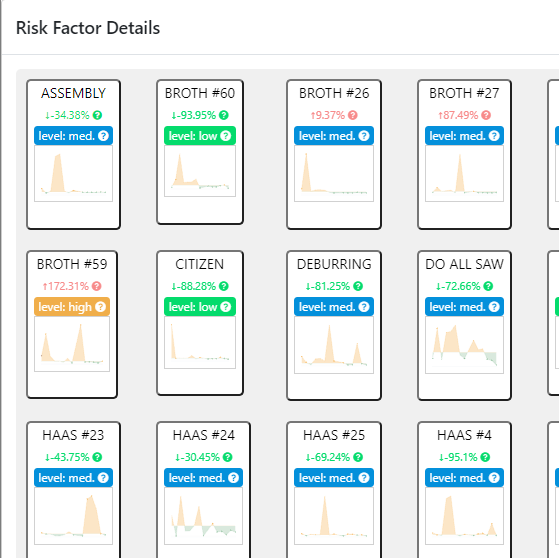

Now, it may come to your mind if you want to know all the intricate risk details about your machines on shop. Don’t worry, we have got you covered! You can select the factor that you want to explore and know about more and Mata’s AI will work its magic based on the preset parameter and find the risk percentage if the job will be completed in time or not, how will it affect the profitability and what can be done to speed up the process along with contingencies in place.

These factors are tailor-made for each client and may change from case to case and its best to get in touch with our team who would be there to help you.