The effect of delays

Running a manufacturing facility is far from an easy task – especially a job shop. As a shop owner or manager, wearing multiple hats is quite an understatement. What we care are usually two main things – are jobs coming in, and can jobs be finished in time. Someone may say quoting accuracy and profitability are just as important. In our opinion, that naturally comes when we can eliminate job delays. More jobs would come and higher profitability would also come. Why? from working with successful shops, we know that clients are willing to pay more if on-time delivery can be guaranteed. We don’t think it’s unfair to say on-time delivery is the corner stone to a shop’s profitability.

Do job delays bother you? For anyone with some experience managing a shop – it’s a given that handling delay is important.

The question is how? It’s true that the most direct way is to look over everyone’s shoulder and constantly check on an order’s status. The problem is – it’s time consuming and that can occupy your whole day and breaks your train of thoughts all the time. Unfortunately, so many shops we have seen operate with this method.

Is there a better way?

What if I tell you there’s a way to predict a job’s future delay with 80%+ of accuracy, and you can know exactly why? Let’s assume if that’s possible, doesn’t it remove a lot of number crunching and free you up so you can do a lot of other important things (such as obtaining more clients, advertising your shop, and perhaps spending more time with the family)?

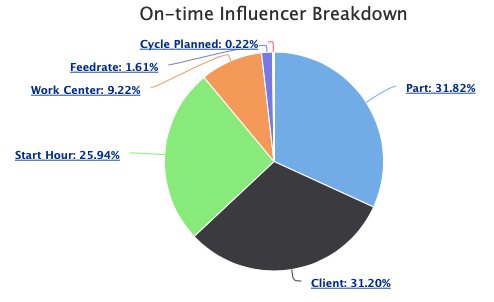

The power of AI (Artificial Intelligence) actually has made this goal a lot more approachable than you can imagine. Best of all, when it finds a possible delay event, it can tell you why that delay happens – it can sometimes be due to a specific client, time of the week, or certain machines with low utilization.

So what’s required? No, you don’t need to invest in many expensive equipment or software to drastically improve your on-time delivery rate. If you already use an ERP or Excel sheets to document and manage your shop floor, a good AI engine can already use those data to find valuable insights and determine the bottlenecks.

Profitability Formula

If you know your shop floor well enough (obviously you do), you most likely already know some bottlenecks you would like to overcome – such as first article taking too long to finish inspecting, underquoted jobs too frequently, etc. What a good shop floor AI can do is, to quantify how these bottlenecks affect your on-time delivery – by how much, and has it been improving or worsening? A typical formula is like this:

Actual Time = Impact Factor × On-time Influencer × Scheduled Time

Here you can see that the influencers are the most important to identify, and the impact factor determines the accuracy of the profitability formula.

Job On-time Delivery Assurance Prediction

It’s important for many industrial applications to supervise the ability to ship product on-time. Here we break it down into four different cases depending on their current vs future on-time delivery capability:

Most Profitable Jobs – jobs that are currently executed on-time, and will continue to be on-time based on AI predictions.

Delayed But Improving – jobs that are currently experiencing delays, but will be on-time based on AI predictions.

Profitability with Potential Delays – jobs that are currently on-time, but are predicted to have delays in the future.

Have Delays and May Continue – jobs that are currently delayed, and will continue the delay trend in the future.

Use On-time Delivery Assurance Prediction to Improve Scheduling

The most difficult challenge when it comes to scheduling is not knowing whether there will be unexpected delays or not. Even though an experience veteran can have a pretty good instinct on what to expect, a good AI engine is able to have high performance in this area. Knowing there are delays waiting to happen in the future, there are two ways to address it – either adjust the quote accordingly, or remove the bottlenecks – whether it be putting more resource on the affected stations or enable live monitoring.

How much improvement can I expect?

Typically, by adopting this method, you should expect 20%+ of efficiency improvement. There are typically three main reasons for a predicted delay – one is some unexpected challenges that come up, second is down-stream stations have severe trafficking (typically the QA stations), third is job scanning not executed timely.

Each scenario has its own unique challenges to fix and some may work better than the other. For example: when an unexpected challenge comes up, it’s important for the shop floor operator to inform the manager/owner and adjust the target. In this case, the communication tool becomes important. Is there a good way for the operators to log the status? Can the manager/owner be informed timely? In another case, when severe trafficking happens, it becomes important to monitor the equipment’s live status to make sure it’s always operating without idle. Lastly, by matching the machines’ live status with the scanning records, we can identify which steps are logged correctly and which are not. Given how difficult it is to create a responsive scanning culture, the machines’ live status can serve as the ground truth for calibration. We will touch on the details on how to eliminate those inefficiency scenarios in follow-up articles.

Mata Knowledge