For decades, companies have been “digitizing” their plants with distributed and supervisory control systems and, in some cases, advanced process controls. While this has greatly improved visualizations for operators, most companies with heavy assets have not kept up with the latest advances in analytics and in decision-support solutions that apply AI.

Fortunately, Artificial Intelligence (AI) and manufacturing automation have become mainstream, trusted solutions for many shop floor issues. When it comes to AI and automation, there are 7 specific areas in which it can help optimize your shop floor. They include:

- The general shop floors

- The inventory

- The Quality

- The machine’s data

- Scheduling and visibility

- The employee’s and company’s safety

- And general workforce

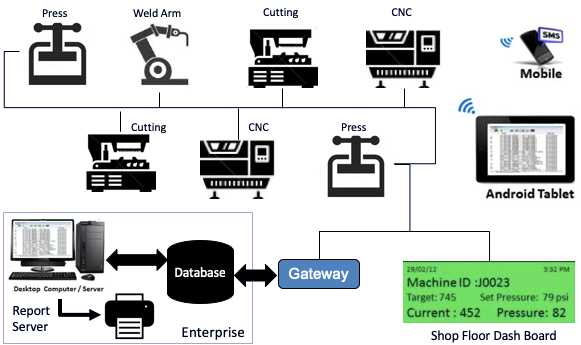

If you have no digitization or automated visibility into your processes, you need to start with descriptive analytics: a system that tells you when your machines are actually running and how many parts, you’re producing so you can optimize their use. With descriptive analytics, for instance, you can identify a machine that’s been sitting idle for two hours at the beginning of every first shift. Optimizing an inefficiency like that can save you thousands of dollars right off the bat.

Next, whether you’re setting up a descriptive analytics system or a more advanced machine monitoring system, you’ll encounter various technological requirements that a partner company can help you identify.

A comprehensive analytic solution-development environment provides visual analytic building blocks to build and test calculations, predictive analytics, and real-time optimization and control solutions with connectivity to real-time and historical data sources and drag-and-drop access to rich functional libraries.

The solution-development environment can provide visual analytic building blocks, allowing users to build and test calculations, predictive analytics, and real-time optimization and control. Solutions are enhanced with real-time and historical data sources and drag-and drop access to rich functional libraries. Solutions are saved as reusable templates for easy deployment to similar assets or process units and permanently deployed into production.